Laser-driven actuator using phase-transition

Purpose

if the optical power of 10 watt laser is 100 percent converted into mechanical power, there will be power that can lift 1 kg object upward at a speed of 1m/s. However, the conversion efficiencies of the current light-driven actuators are very low. We are searching for a way to convert light energy into mechanical energy efficiently. One of the final goals is to demonstrate a light-driven actuator that can drive a macroscopic objects.

Types of light-driven actuators

There are several types of actuators. See review. The most common type is a thermal expansion, but generally their conversion efficiencies do not reach even 0.1%. One of the reasons for the low efficiency is the energy loss due to the heat dissipation. Therefore, if one do not need to raise the temperature the conversion efficiency is expected to be much higher. One of these processes is the phase transition. In phase transition, the temperature do not change very much yet the volume or length can change dramatically.

The material we used for this study

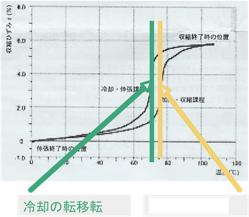

We used a commercially available Ti-Ni alloy wire. The phase-transition temperature is 70 degrees Celsius and above this temperature it shrinks about 5% in length.

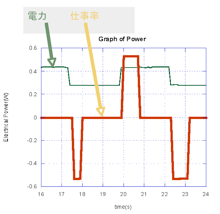

The length is shown in the figure. It forms a hysteresis curve. When it shrinks it absorbs heat and when it extends it emits heat. The difference between these curves causes a loss. In this study the heat dissipation and the loss due to the hysteresis will be evaluated and their relations to the energy conversion efficiency will be discussed.

The design

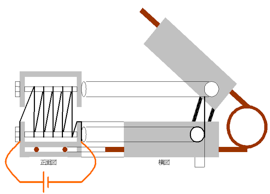

The light actuator is composed of two V-springs. These two springs are fixed by aluminum channels. At each end of aluminum channel near fulcrum of spring, plastic screw is piercing through each aluminum channel, perpendicular to spring. To two plastic screws, wire is coiled alternately. This wire is composed of Titanium and Nickel, which makes wire sensitive to temperature and causes phase transition at 70 degrees Celsius. The compression of wire attracts two plastic screws, causing movement of aluminum channel also. The power act on aluminum channel by this method is mechanical power of actuator.

Method

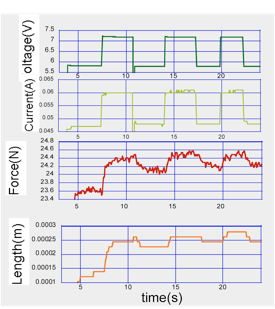

A bias current is supplied to the wire to bring its temperature to just below the phase-transition temperature. In our setup it was achieved when the voltage of 6.0V was applied. The current was 45mA.

The force and the travelled distance were measured with PASCO sensors.

Result

A bias current is supplied to the wire to bring its temperature to just below the phase-transition temperature. In our setup it was achieved when the voltage of 6.0V was applied. The current was 45mA.

The conversion efficiency was estimated from the following formula

電気的入力(W)=

投入電力 - バイアスの電力

Wf - Wi

機械的出力(W)

= 力 × 速度

{ F(m/s^2)× v(m/s) }

Future plan

Compared to the thermal expansion temperature induced phase transition has an advantage that the temperature increase is minimal and that the heat dissipation is much less. This leads to a much higher energy conversion efficiency.

There still are some heat dissipation. If one could use a light induced phase transition this problem will be evaded and one can expect an even higher conversion efficiency. We are currently investigating a material suitable for this purpose.

Movie

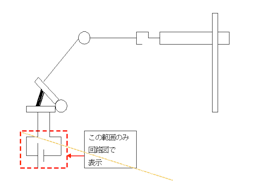

Click on the picture to start the movie of the working prototype of the actuator. A 1064 nm laser beam irradiates the wire located near the spring. When the laser is on the actuator goes down and when the laser is off it goes up. The movie is in AVI format.

形状記憶合金を利用した光駆動アクチュエーター

For details please read: H. Okamura, K. Yamaguchi, and R. Ono, "Light driven actuator with shape memory alloy for manipulation of macroscopic objects", International Journal of Optomechatronics, 3, 4, 277-288 (2009)